Advantages

Productivity

- Automatic regulation of air volume supply, adapted to compressed air demand

- No shutdown necessary = longer service life

- Heat is generated even with low compressed air demand

- High overall efficiency

- Economical operation

- High operational reliability

Costs

- Combined generation of compressed air and heat

- Higher efficiency = reduction in energy losses = cost reduction

- Higher thermal output due to heat pump effect

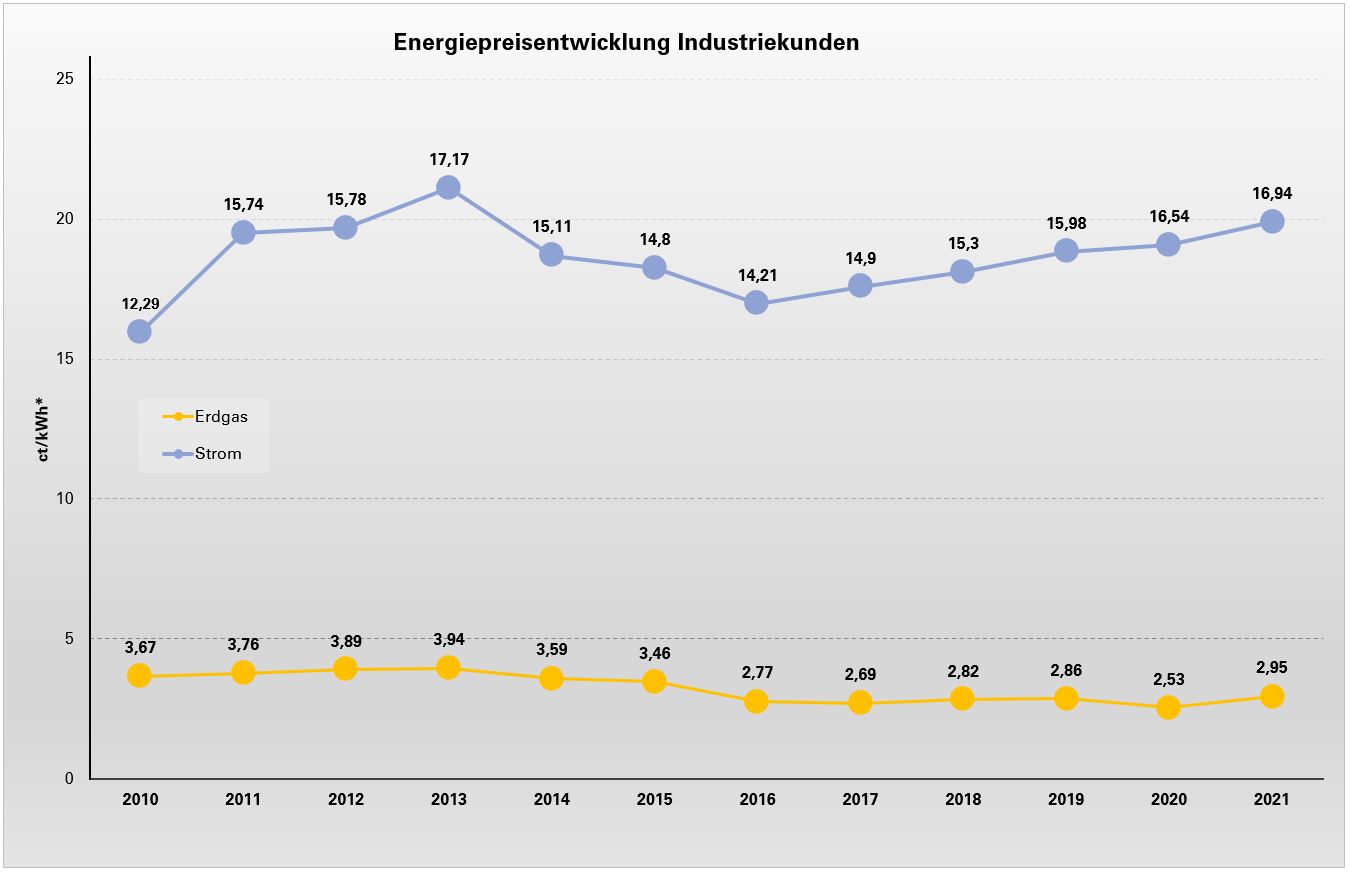

- Natural gas cheaper than electricity

Costs of conventionally generated compressed air

Compressed air is the most expensive form of energy produced from electricity. The efficiency of mechanical compressed air generation from electricity is approx. 5 percent. That means: from 100 percent energy from electricity, about 5 percent energy from compressed air remains as a rule of thumb for compressed air. Or: To generate one energy unit of compressed air, 20 times as many energy units of electricity must be invested. 20 x 15 cents = 3 euros In addition, up to 50 per cent of this expensively generated compressed air is lost again in a large number of industrial plants. Thus, the value of an energy unit of compressed air increases to 40 times the value of an energy unit of electricity. 40 x 15 cents = 6 euros When air is compressed, mechanical energy is converted into thermal energy. Due to the pressure difference before and after compression, mechanical work can be done by expanding the air. For this purpose, heat is absorbed from the environment, so that physically 100% of the mechanical energy used is available as heat. This heat is often seen as a waste product and is not used at all or only partially with a small proportion.

Costs and advantages of compressed air generation with gas

Due to the heavy burden of electricity prices with apportionments and levies, the CAHS in industrial use quickly pays for itself compared to conventional compressed air generation. In addition to the clear economic advantages, the system also has ecological benefits compared to the separate generation of compressed air and useful heat: For example, the use of the altAIRnative CAHS’s 08/630 leads to an annual saving of 315 tonnes of CO2 compared to the separate provision of compressed air and heat for an operating time of 8,000 hours.

*Net energy prices for industrial customers, arithmetic mean, excluding VAT. Source: Statista GmbH, Gas and electricity prices for industrial customers

Environment & optionality

- Environment & optionality

- lowest greenhouse gas emissions and particulate matter pollution of all fossil fuels

- CO2 emission reduction

- The heat extraction is adapted to the customer’s requirements

- Exhaust gas and condensing heat exchanger

- Compressed air cooler

- Modular design – highest possible degree of flexibility

- Sound insulation bonnet

- Integrated or remote control cabine

- Integrated catalyst for technically oil-free compressed air