How the CAHS works

The function of a CAHS differs from conventional compressors primarily in the way it provides the mechanical work needed to generate compressed air. This is provided not by an electric engine but by a gas engine coupled to the compressor shaft. Through variable-speed operation, the amount of compressed air is supplied according to demand. In addition, the heat generated by the engine and exhaust gas and the heat to be dissipated during compression are utilised in the extremely interesting temperature range of 70 – 90°C. The CAHS has already developed a standard system for this purpose. Here, the CAHS already develops a thermal efficiency of approx. 90% as standard. Optionally, an increase to over 100% can be achieved by additionally utilising the exhaust gas’s condensing effect and the compressed air’s condensation heat. The flexibility of the CAHS allows heat utilisation in the temperature range of 40 – 108°C. All components are installed on a compact, stable system support, which is supplied soundproofed and thermally insulated and installed at the customer’s site in a vibration-decoupled manner.

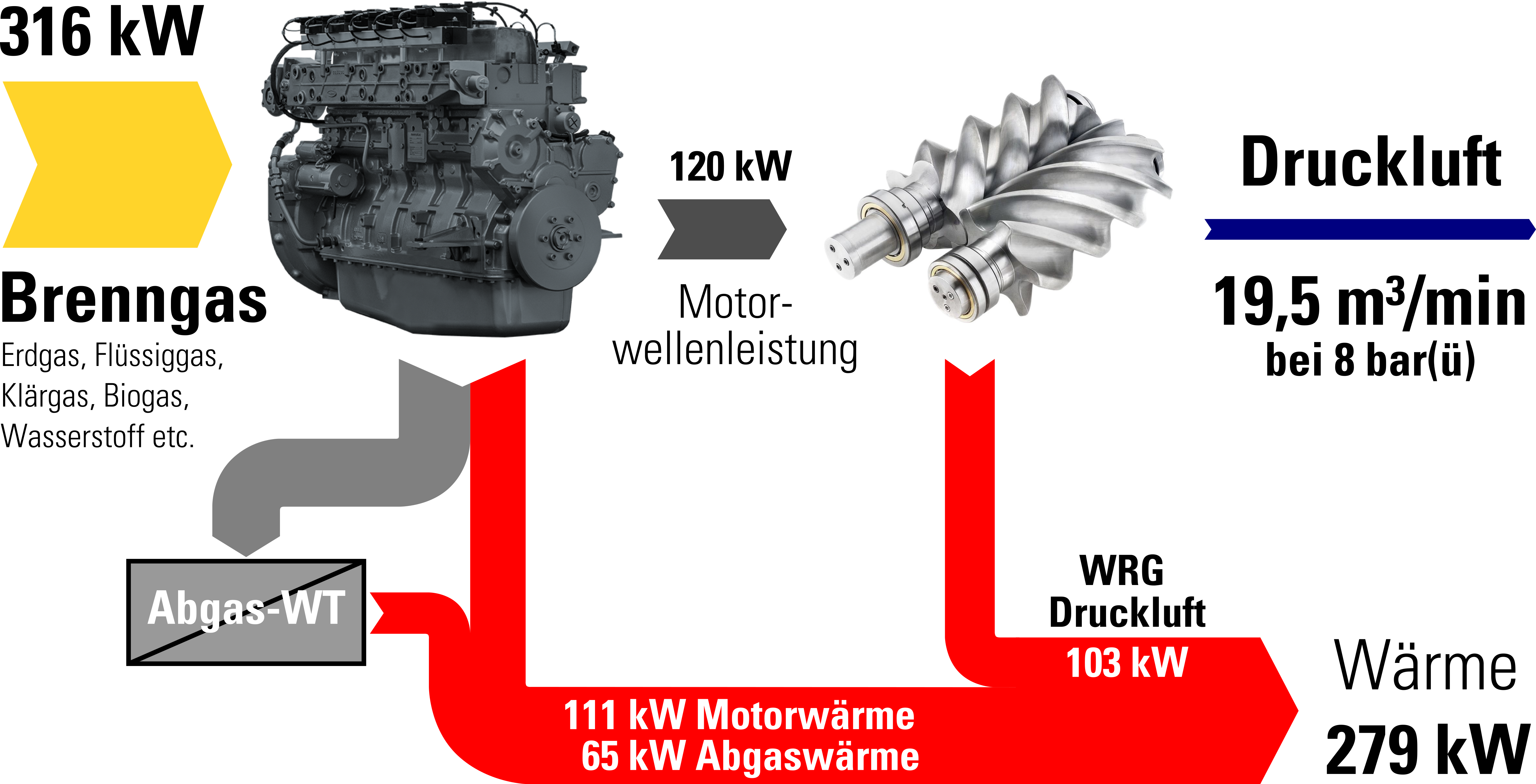

Image: energy flow diagram CAHS